Command Alkon offers a leading supplier-collaboration platform for the construction industry to replace complex manual tasks and processes with efficient, scalable, and reliable solutions. These solutions, which provide vehicle telematics and other data and diagnostic insights, deliver improved results through lower operating expenses and improved business processes. The Digi Wireless Vehicle Bus Adapter provides the connectivity for their telematics solution.

Streamlining the Concrete Supply Chain

From skyscrapers to roads and bridges, concrete is a fundamental requirement for successful construction projects. The vehicles that carry ready-mix concrete, aggregate, sand, and other materials from the factory to the job site are a crucial component of this supply chain.

Larry Curtis, Vice President of TrackIt, the telematics business unit of Command Alkon, says that when it comes to transporting concrete, time is of the essence. “Generally concrete has a two-hour shelf life from the time it’s put on an expensive truck to the time it reaches an expensive job site,” he said. “And it’s not just one truck delivering one load. We’re typically sending a series of round-trip deliveries and the concrete needs to be poured into place in a continuous sequence. So there’s a lot riding on and in these vehicles, and careful management is required to ensure timely delivery of a high-quality product.”

Curtis noted that construction is a very dynamic environment, and a variety of factors merit close monitoring, including regulatory compliance for driver safety, driving performance, vehicle maintenance, and more.

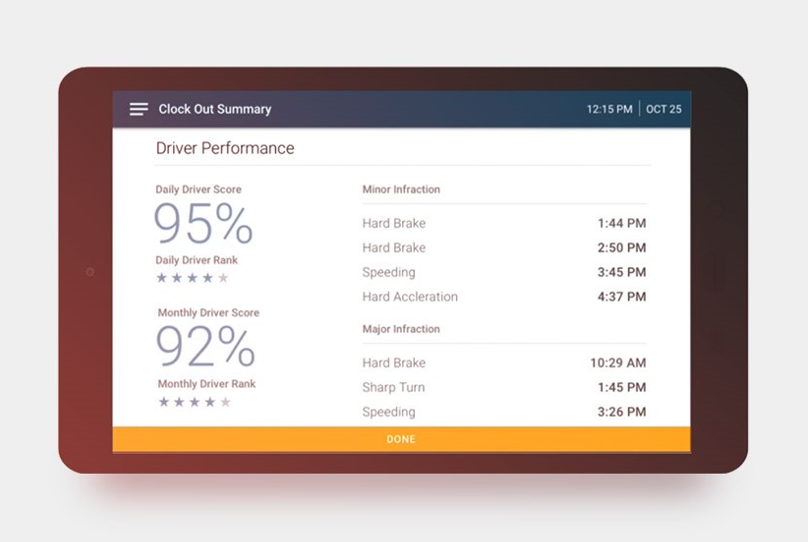

“We have so many variables to manage,” he explained. “For instance, the driver’s service hours-per-day are carefully limited by federal mandates to ensure safety, but we also monitor that driver’s performance. Is he braking too hard, speeding, or swerving? We need to know the fuel status, engine temperature, and other diagnostic data, as well as the vehicle location. Is the truck on the way to the job or returning? If the job is behind schedule, we’ll slow down subsequent deliveries, but if it’s ahead of schedule, we have to speed up our dispatches to the site. So we’re looking to capture and transmit a lot of real-time data on a constant basis.”

Driving the Fleet to Greater Efficiency

Seeking to respond to these needs for construction companies, Command Alkon developed TrackIt, a single platform to manage and seamlessly integrate all in-cab telematics and provide complete visibility to the entire truck fleet. TrackIt offers GPS truck tracking and telematics as well as fleet and workforce management – specifically for heavy building materials suppliers and haulers. “We needed a device that would be simple to deploy and use and wouldn’t require external antennas or Internet connections,” Curtis said. The goal was to create a consistent connection to deliver data to and from a truck-mounted table.

“We wanted to work with Noregon, who is a recognized leader in engine-diagnostic software, and we wanted simple and reliable connectivity as well. That’s when we turned to the Digi Wireless Vehicle Bus Adapter.” This rugged, compact plug-in device provides easy access to vehicle data via standard Wi-Fi and web services. The Digi WVA installs in minutes by connecting directly into the diagnostic port of the vehicle, which speeds deployment. Low-cost hardware and an efficient installation make the Digi WVA ideal for vehicle fleets.

Curtis added that Digi’s device monitoring and management platform, Digi Remote Manager®, enables the company to monitor the devices centrally and update them when needed. “Using Digi Remote Manager, we can get to all the devices in the field. At this time we have about 10,000 Digi devices in the field, but we have about 40,000 trucks out there. We can scale up easily.” As the company continues to build more software feature sets, they can quickly push out the updates to all deployed devices.

“Digi was an excellent choice for TrackIt,” said Curtis. “It is compact and ruggedized and easily connects to the diagnostic port with just one cable connection. We liked the simplicity of the product. It doesn’t require antennas or complex wiring and it tucks under the dash so it’s out of the way. With the exception of some older trucks, the device draws all its power from the diagnostic port. Digi is a proven, financially stable company with a good reputation, so this was definitely the right choice for us.”

In the TrackIt solution, Digi WVA is the Engine Data Connector, providing the actual device and data delivery, and Noregon solves the challenge of aggregating different truck manufacturers, models, and data types, Curtis explained. “After a six-month trial period with some very basic software modifications, TrackIt now plugs into 95% of vehicles in our market and delivers high-quality data via Wi-Fi to a tablet in the truck cab.”

A Concrete Solution

Using TrackIt, concrete manufacturers gain real-time visibility into the fleet and mapping of individual trucks as well as the ability to analyze jobs, routes, productivity, and performance while improving customer service. “In addition, we can really drill down on every engine in the fleet,” said Curtis. “That means everything from temperature and oil pressure to battery voltage to other vital engine-metrics. That improves preventive maintenance and extends the life of the vehicles. When a Check Engine light comes on, the dispatcher gets a real-time alert and he can decide whether to continue the delivery without risk or shut down the vehicle.”

TrackIt also presents a compelling ROI as well. “With more efficient routing and smarter and safer operation, if you save even a half gallon of diesel fuel a day, it adds up. At $4 per gallon and 1,000 vehicles, you’re saving $2,000 per day – just in fuel costs. In fact, one of our customers with a 57-truck fleet increased its fuel economy by 25% after only two months of monitoring engine events.” Curtis added that TrackIt also automatically records driver hours and mileage, which eliminates the need for paper timesheets, making life much easier for the drivers.

Since selecting the WVA in 2018, Command Alkon has installed over 10,000 devices and has identified another 30,000 trucks for future deployments. “The Digi WVA installs easily and performs reliably, and Digi Remote Manager also makes it easy to manage a fleet of devices. That enables us to continue to focus on refining and expanding the tools we can offer our customers.”